Carpet backing

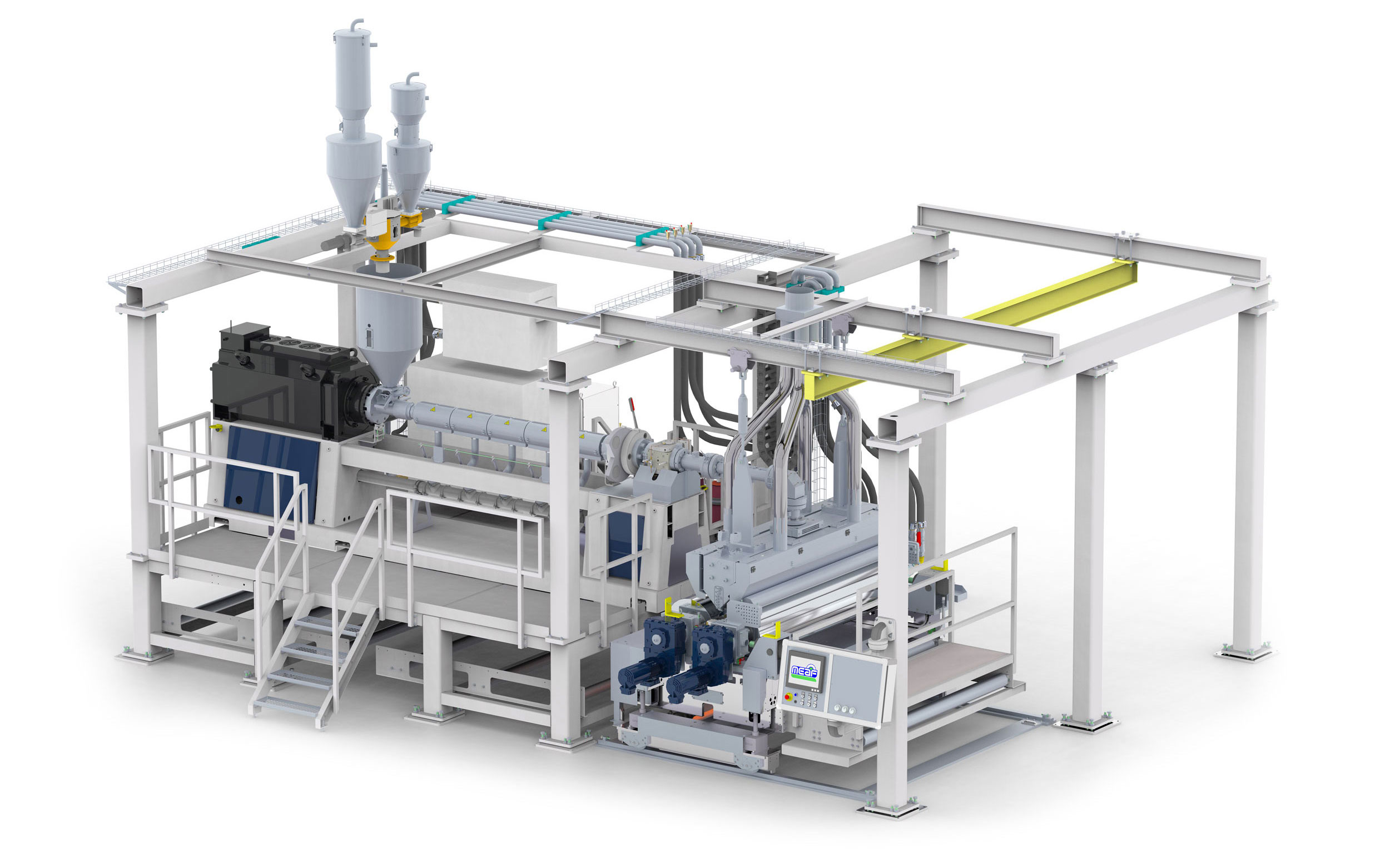

When looking to meet your customer demands for a carpet which is not only custom-made but also sustainable and recyclable, the MEAF extrusion lines for thermoplastic elastomers (TPE), thermoplastic olefins (TPO), thermoplastic rubber (TPR) and thermoplastic urethane (TPU) are the answer to your desires.

Even when you are considering adding a precoat of Polyvinyl Butyral (PVB) or Polybutene (PB1) our extrusion lines can accommodate this without any modifications required to the traditional thermoplastic extrusion lines.

Our extrusion lines are optimised to work with a variety of materials (even with lower melt temperatures such as PVB and PB1) and are optimised to extrude the thermoplast directly onto the carpet. In addition to the extrusion, we can also accommodate the integration of a fleece as secondary backing, coating/lamination of the backing with other polymers such as PP or PE and/or filling with high concentrations (≥ 60%) of the backing with a mineral such as CaCo3.

As many of your customers require a custom-made backing with a logo and/or an embossing to be added to the carpet, this can also be achieved with our extrusion process by adding a surface design to the middle chromium roller in our roll stack.

Looking for a recyclable carpet backing or working on redefining your production process? Our specialists are more than happy to discuss your project, choice of material (compound) and assist you from the initial project start-up, through the testing on our in-house extrusion line and onwards to a fully functional, energy efficient production line being operational in your factory.