The MEAF H-series extruders are equipped with an energy efficient design and optimisation of key-components, consisting of:

- Screw- and barrel design;

- Heating element configuration;

- Temperature profile during sheet extrusion;

- Insulation of key components in order to reduce energy loss to the ambient air.

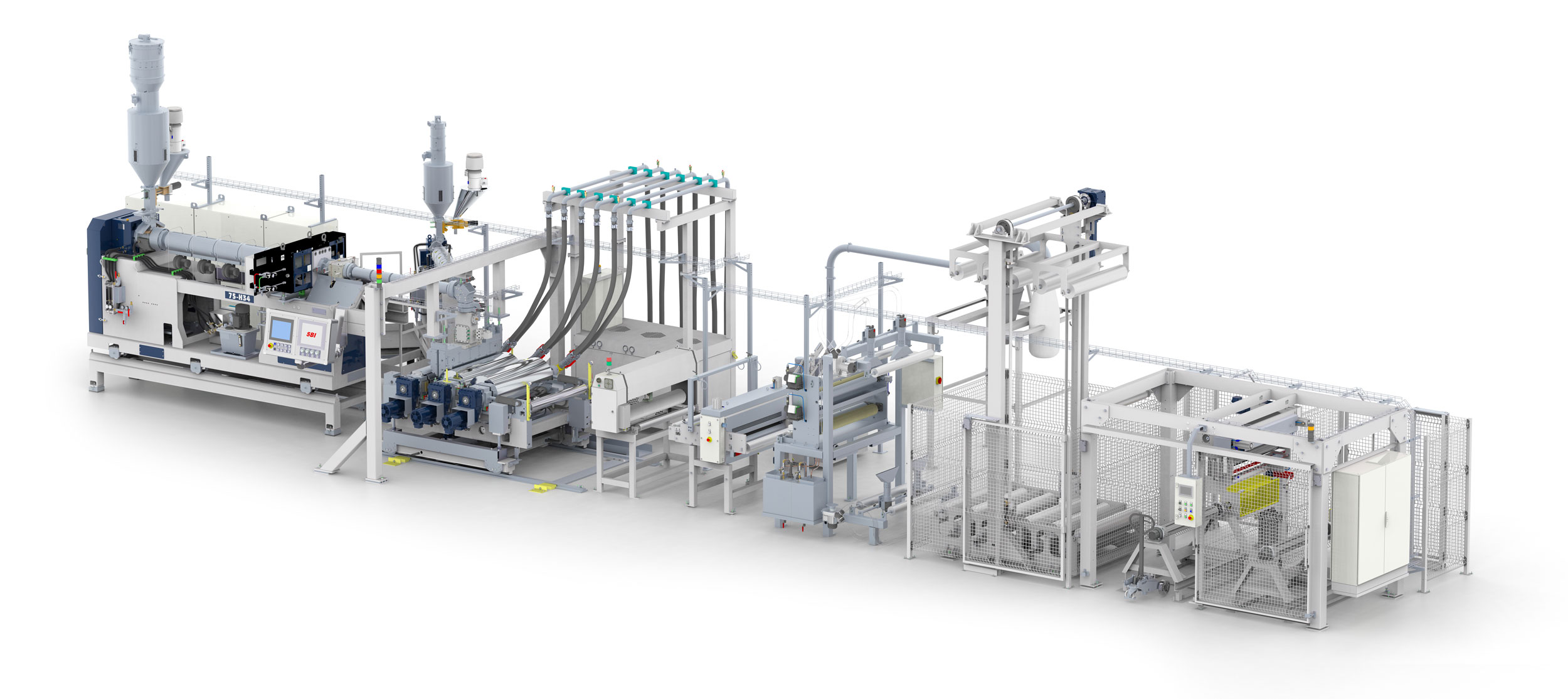

This complete package ensures that the MEAF sheet extrusion line provides you with a flexible, versatile and the most energy-efficient sheet extrusion line in the market today.