MEAF’s X-Tender project: post-condensation polymerization processing

As the great Thomas Edison once said: “There’s a way to do it better – find it.”

That is exactly what is part of MEAF’s company DNA when it comes to innovations on our machines. Recycling of materials, with the main focus on PET, is becoming a more and more important part of the plastic production process.

As a company continuously innovation and researching for a more sustainable, energy efficient and full circle recycling way of producing sheet extrusion lines for the packaging industry, MEAF has received a Demonstration of Energy and Climate Innovation (DEI+) grant from the Rijksdienst voor Ondernemend Nederland (RVO) to further develop the X-Tender project.

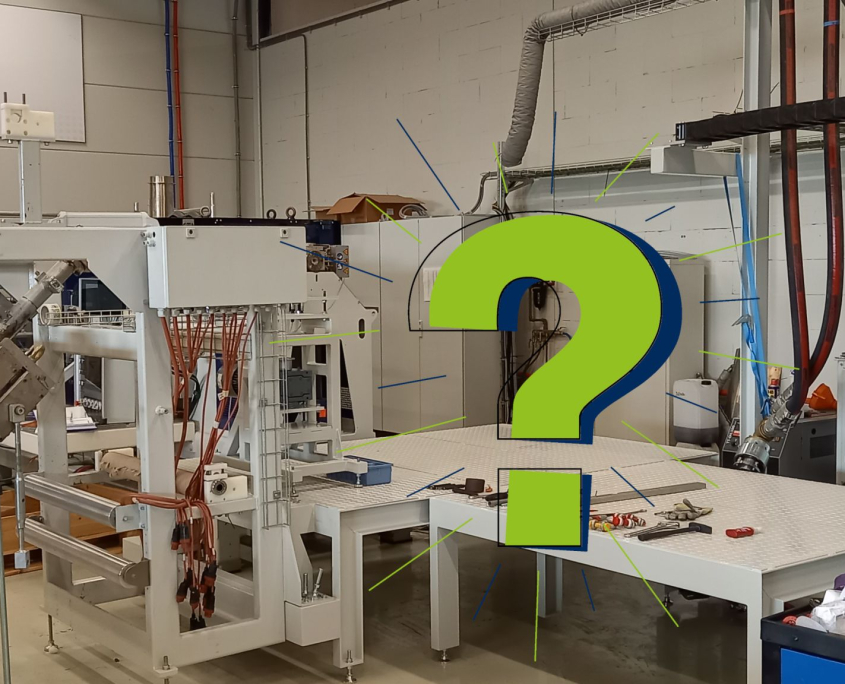

The objective of this project is the development of a new type of polymer post-condensation polymerization processor. The processor stands out compared to the current state of the art equipment in terms of:

- Energy efficiency;

- Intrinsic viscosity (IV) increase;

- Relative size;

- Integration flexibility in existing extrusion & recycling lines;

- Total investment (CAPEX);

- Maintenance costs (OPEX).

This grant provides MEAF with the financial backing to further develop the X-Tender project into a full scale production unit. The receipt of the DEI+ grant could not have happened without the diligent work and assistance of consulting firm Ugoo.

Busy times at MEAF Machines in April and May!

It has been very interesting and busy times at MEAF in April and May. We had the pleasure to welcome potential customers, representatives and long-term partners from around the globe in our factory. In the time span of less we were honoured to have visitors from China, Jordan, Indonesia and Italy!

MEAF welcomes RON Extrusion as new Global Service Centre

We are delighted to announce that we have appointed RON Extrusion Engineering as our newest Global_Service_Center (GSC). This GSC will provide Technical Support, Installation & Commissioning Services to our complete portfolio. After getting intense training at the MEAF factory, we are trusting in RON’s capabilities to assist our customers with technical support and installations.

Above picture:

Hosting of plastic industry innovators & industry leaders

It is not often that we at MEAF Machines B.V. are honoured with a visit of not 1 but 2 living legends in the plastics industry! We had the pleasure of hosting both Mr Giuseppe Ponzielli as well as Mr Chris Rauwendaal to celebrate together with our colleagues Elwin Houtekamer, Rony D’hollander, Nelleke and Karel Houtekamer the induction of Chris in the Plastics Hall Of Fame in 2024.

Once again from all of us at MEAF an heartfelt congratulations and well-deserved “hats off” for this tremendous achievement!

Click here to add your own text

Join MEAF at various exhibitions around the globe!

The upcoming months MEAF is attending (together with our local representatives) the following exhibitions:

|

When: | May 21 – 24, 2024 |

| Where: |

Targi Kielce Congress Centre 25-672 Kielce, Poland |

|

| Booth#: | A-28 | |

| MEAF partner: | Invester Sp. Z.o.o. | |

|

The International Fair of Plastics and Rubber Processing PLASTPOL is Central and Eastern Europe’s largest event for the plastics processing industry Through our local representative, Invester Sp. Z.o.o., we welcome you at our booth during the PlastPol 2024! |

||

|

When: | September 10 – 12, 2024 |

| Where: |

Landmark Centre Lagos, Nigeria |

|

| Booth#: | 2C13 | |

| MEAF partner: |  |

|

|

Propak West Africa is West Africa’s BIGGEST exhibition and conference for professionals working across the packaging, plastics, printing, and food-processing industry. Through our local representative, Formtech Thermoforming , we welcome you at our booth during the Propak West Africa 2024! |

||

Planning to visit any of the above exhibitions? We are looking forward to discuss with your our “green extrusion solutions, consisting of:

- Energy consumption reduced up to 65% compared to our competitors

With the production costs of electricity rapidly rising, MEAF’s H-series extruders provide an energy efficient alternative to reduce energy costs without compromising on quality. - Material usage reduced with environment friendly physical foaming technology

Integration of physical foaming technology from Promix can be integrated to achieve density reductions between 10 – 30% whilst retaining stackability and product strength properties. - Improved recyclability of carpets, artificial grass and automats

MEAF’s extrusion coating for thermoplastic elastomers (TPE), and others such as TPU and PVB, provides the possibility to produce a fully recyclable and sustainable product backings.For these applications we partner together with EOC Group as compound supplying partner. - Produce monolayer products with 100% regrind and FDA/EFSA approved food grade sheet

Our extruders are designed to work with 100% regrind incl. bottle-flakes and can assist you with “tray to tray” production.

Our sales team and our local partners are looking forward to meeting you at any of the above exhibitions around the world!